Back in October ("Plastics vs. Brightwork") I started removing the toe-stubbing teak from around the aft deck lockers. Hurricane Irene indicated that it may be part of the leak into the aft cabin. After busting up the wood, we had to fill all 56 screw holes with epoxy.

Then wait a day until the epoxy is cured. However, since we're only here on weekends, that means wait a week while the epoxy cures. Add some Non-Boat Weekends and it takes us a month to redo our hatches.

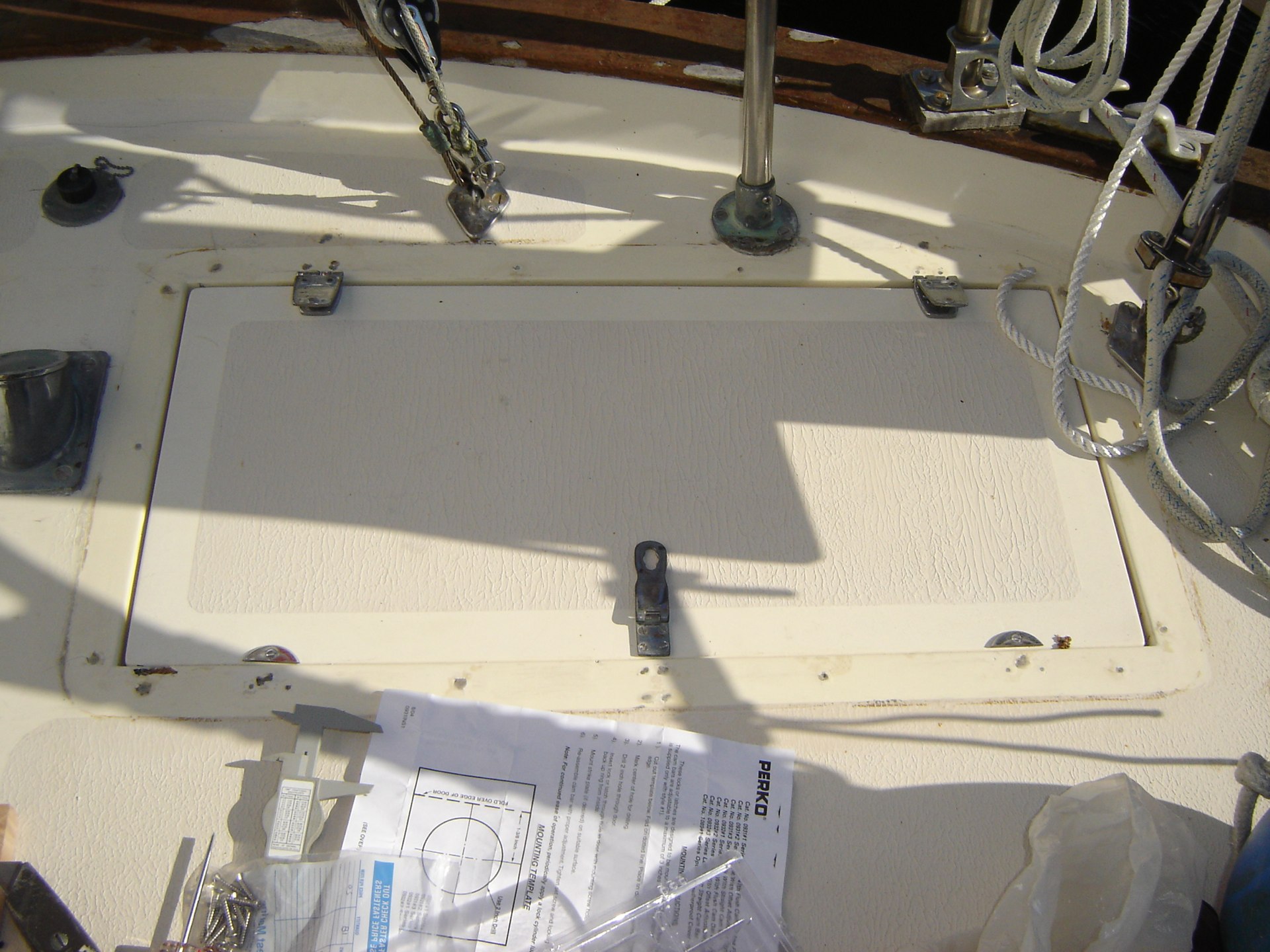

Once the wood was off, I could install flush-deck latches instead of painful to step on hasps.

We like the look of the Perko latches. It did involve drilling a 2" diameter hole in each of the hatch covers. This exposed balsa core material, which required careful wetting-out with lavish amounts of epoxy. Since we have to wait for that to cure, the job stretches to another day.

Here's CA cleaning up the Boatlife caulk we use to seal the latches to the deck. I'm hoping that this will minimize water intrusion.

The final step (after waiting another day, and possible another weekend) is to install the latch underneath the handle.

And yes, the screw holes filled with epoxy are completely visible. We did nothing to hide them. Maybe someday we'll paint the deck.