It's embarrassing but true: Red Ranger's electrical system has been an opaque mystery. Yes, I have done electrical work (i.e. add battery fuses and rearrange the grounding) but there's a difference between a pile of parts and an integrated whole. I was mired in "crap-load of components" mode until yesterday.

What changed? I'm not sure, but my understanding suddenly crystallized.

The fundamental question is "How Healthy Are My Batteries?" More importantly, we need to know how long Mr. Lehman must work to recharge them. Answering those questions is actually difficult. There are three kinds of battery tests: open circuit voltage, a "load test" (which is quite wearing on the battery) and an examination of the electrolytes (which only makes sense for a wet cell battery you can open.)

None of these tests, by the way, can be run while the batteries are being charged. You don't know if they're charged until you stop charging them and let them rest for several hours. Sigh.

In the process of doing the open circuit voltage test, I learned many, many things.

Embarrassment of Riches

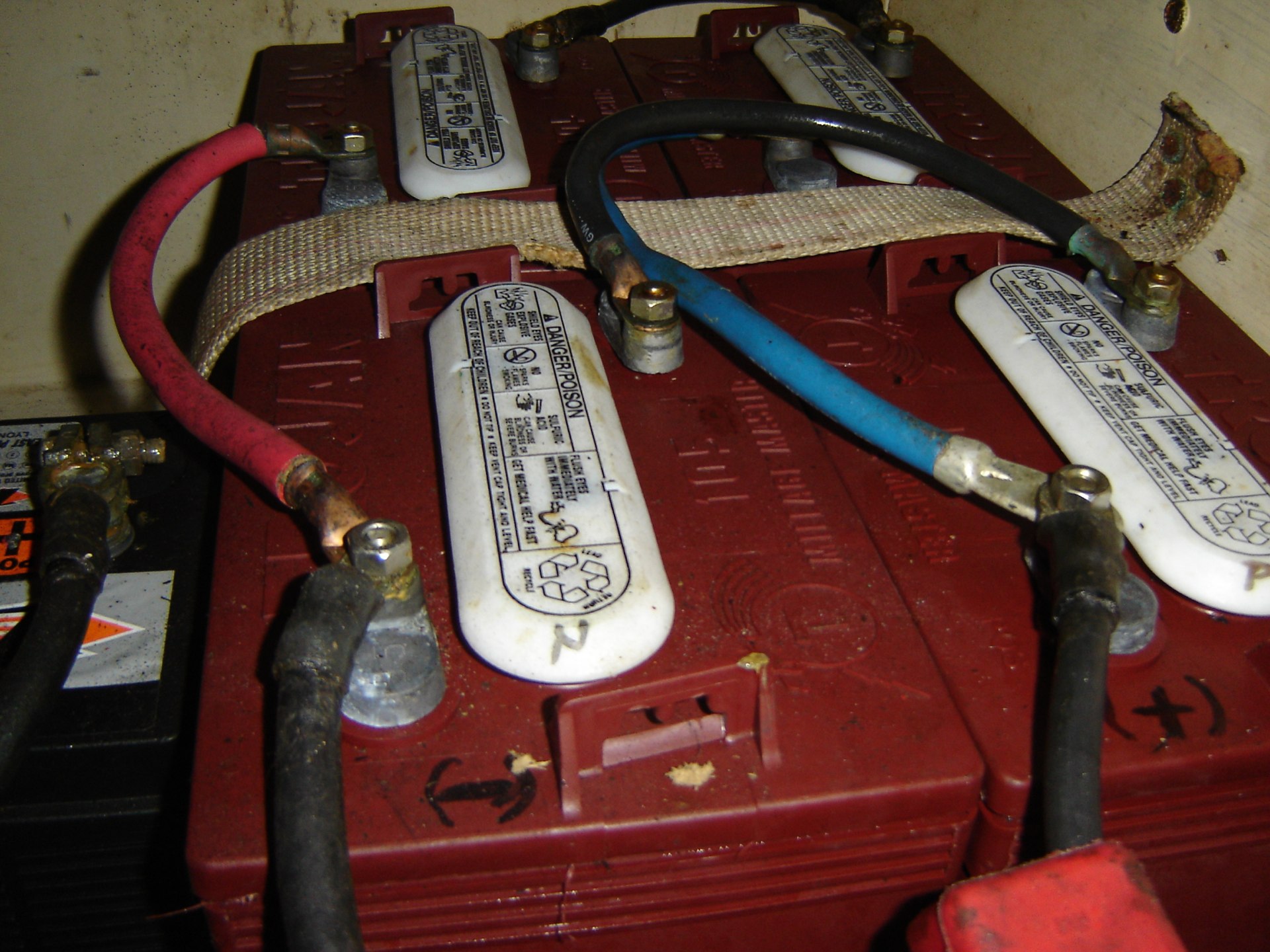

First, the house batteries are four Trojan T-105's in series and parallel with a total of 450 amp-hours of power. For some reason, this simple identification of the batteries eluded me until yesterday. Embarrassing.

Second, the panel voltmeter is approximately useless. Yesterday, I found the the Trojan T-105 User's Guide. (Yes, big batteries have a user's guide.) The guide has a table with the open circuit voltage and level of charge. This table is a life-or-death kind of thing. Glad I finally looked for it.

Clearly, the 80's-era analog panel display with a range of 0 to 20 volts was never precise enough for the required measurements. An analog meter that shows just the 10-16V range would have been much more useful (you can even buy one with color-coded bands around some important voltages.) A digital meter seems even better for this task. I finally ordered a state-of-the-art meter so I could actually monitor what's going on.

Third, the alternator should put out something between 13.8 and 14.2 volts when the engine is running. So we have to check both open circuit voltage (everything off) as well as charging voltage.

I think this "test procedure" view point is what helped clarify things for me. What am I measuring? What does it mean? How do I measure it? (Also, it may be that our fuel system problems appear solved; rather than think about Mr. Lehman, I can think about other things.)

It turns out that batteries have an amp-hour acceptance rate. The rule of thumb for wet-cell batteries (like the T-105's) is 25% of the overall power, which is 112 amp-hours. Our 70 A alternator, therefore, may be under-sized for our house battery system. Nigel Calder's Boatowner's Mechanical & Electrical Manual: How to Maintain, Repair, and Improve Your Boat's Essential Systems covers the various ways to solve this problem.

The Math, FWIW

Voltage, v, given fraction of available power, a, from 0 to 1.

More importantly, fraction of available power, a, given voltage, v.

From the voltage, we can gauge the amount of battery life remaining.

Or this.

| Volts | Life |

|---|---|

| 12.7 | 0.95 |

| 12.6 | 0.88 |

| 12.5 | 0.81 |

| 12.4 | 0.73 |

| 12.3 | 0.66 |

| 12.2 | 0.59 |

| 12.1 | 0.51 |

Budgets

An electrical system strikes a balance between supply and demand. While embarrassing, I (finally) figured out that we have a 450 amp-hour supply. We can't actually use all of that. There are two reasons.

First, a battery can only stand a few deep discharges. It can stand 1,000 discharges to 50%. But only a handful to 0%. Some batteries can stand only one discharge to dead. The standard recommendation is to discharge your batteries no more than ½ way.

Second, the size of our alternator defines how long we need to run the engine to recharge our batteries. We can't simply use a huge alternator because we're also limited by the charge acceptance rate. If we use 210 amp hours of lights and entertainment and microwave popcorn, we have to run the engine for over 3 hours to recharge. If we limit ourselves to 70 amp hours each day, we only have to run the engine for an hour to recharge. (A typical sailing trip involves about an hour of motoring in and out of Jackson creek.)

A boat has three electrical budgets.

-

Dock-side. 80% of boats seem to spend their lives tied to docks. At the dock you have cheap, reliable 110V AC power from the marina. You can make microwave popcorn, run all the air conditioners and watch television on your two 30 A shore circuits. You don't need (or use) batteries. Red Ranger has six 110V electrical outlets plus two 110V lights for gracious shore-side living and entertaining. (We ripped out the TV, microwave and one of the two air conditioners.)

-

At anchor. Anchoring means living within your means. (This is what we love about boating. Really.) If we use 70 amp hours per day, Mr. Lehman works an hour each day to recharge the batteries. (About $3.80 per day of diesel fuel.) If we add a 20 amp hour solar panel, we reduce the engine charging time. Or, perhaps, we could reduce demand to 35 amp hours each day.

-

On passage. On passage means using lots of boat systems: radio(s), chart plotter, running lights, pumps, autopilot, fridge, instruments. It also means potentially running these things 24 hours each day with no easy way to cut demand.

Red Ranger's initial budget looks like this:

This is based on an inventory of every electrical draw we could identify. Note that this does not include any provision for refrigeration. It also assumes that we keep our existing incandescent lights and use every bulb two full hours each day at anchor. We'd be hard-pressed to actually use 70 amp-hours.

It also assumes that our iPhone and Kindle charger uses 20 amp hours. We don't know the real draw; only the stated maximum of 120 watts.

Note that passage-making requires running the engine for two hours every day. It also shows that our batteries are only 30% discharged on passage, meaning we have an ample safety margin.

Next Steps

We've ordered some digital panel meters to start managing our energy supply and demand. The volt meter is easy to install. The ammeter is a bit more complex because of the high-precision shunt. Also, a bilge pump cycle counter will help us understand how often that kicks on.

We've ordered a few LED lighting components; this will start to reduce demand. Once we have accurate measurements, we can continue replacing old incandescent lights with low-energy LED lights. We have six old-school cabin fixtures to replace; that's perhaps the highest single cost. We should also replace our mast spreader light, even though we use it rarely.

We need to read (and understand) Nigel Calder's advice on how to improve the output from our alternator.

Also, our circuit breaker panel has a random-seeming mixture of white and green switches. The switches are almost all Sensata Airpax SNAPAK Toggle-Handle Breakers (T11-2-15.0A-04-20 and T11-2-15.0A-06-20); except for three non-SNAPAK horizontal switches. I want to replace the three horizontal breakers with SNAPAK vertical switches. I would also like to rationalize the green/white colors in some way.

There's nothing so motivating as an embarrassing gap in one's knowledge.