Many boats are hauled out and winterized in the fall. In the frozen north, it's essential to prevent damage to all systems with water in them; specifically, freshwater, heads and engine. But in Middle Peninsula — Deltaville, VA — haul-out seems to be optional. Some days are a bit too chilly to sail, so rather than winterize, we'll try to get some maintenance done.

Wind Instrument Alignment. When our masts were restepped the wind instruments weren't totally centered up again. The fix involves ascending the mast and the fiddling with the displays on the nav station and helm.

I wish I had taken pictures of CA at the top of the mast. Sadly, she had the camera up there. But the clinging to the mast part of the job made it hard for her to take any pictures from 55' above the waterline. Next time, we'll get some pix.

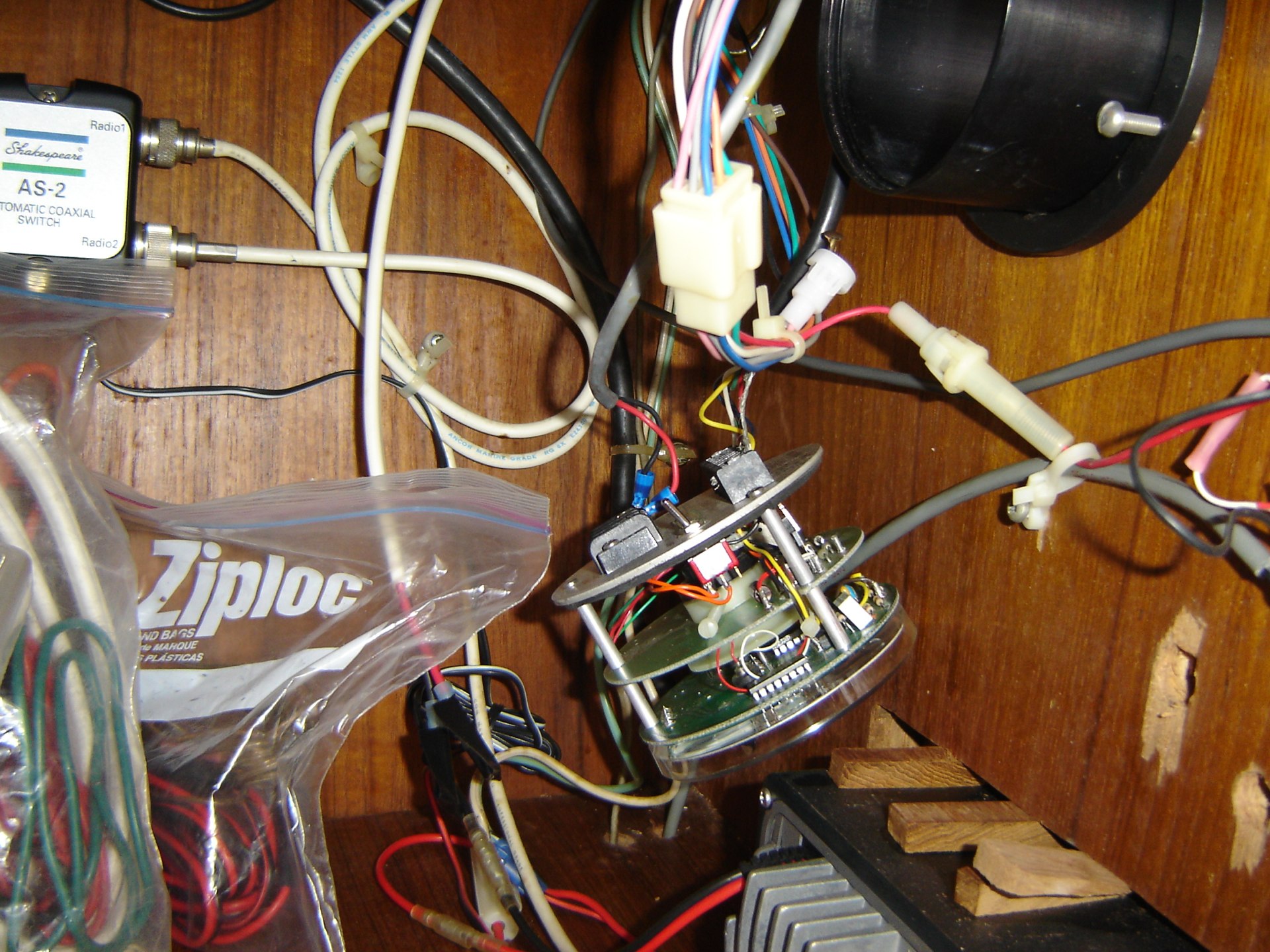

Once I was inside the nav station, I ripped out the old GPS wiring harness and generally cleaned things up. There's a bit more to do to get ready for a new VHF radio, computer and chart plotter.

Sail Cover recut. The Sailrite stackpacks tend to be rather tall. CA doesn't like the amount of windage in the baseline stackpack design.

So she put darts into the stack. It changes the top-edge from a straight line to a curve that reduces the overall profile to something smaller.

Life Line Stanchion Wobbliness. Our taffrail lifeline stanchions are wobbly. We took some careful pictures of Joie de Vivre which has some extra supports for her davits.

I think I have an improvement in hand. I'll have to spend some quality time with West Marine buying lifeline or perhaps dodger parts. This will be a few feet of steel tubing, deck fittings and miscellaneous bits and bobs.

What makes this a little confusing is that the lifeline base is solidly mounted on the deck. It doesn't weep a drop of water. It's the stanchions that are wobbly in the base.

Fuel Polishing. After our fuel filter clog-ups, we need to take some action. We either need a Racor 75-500 MAX or a Gulf Coast GCF MODEL FPS 040B. Both are complex installations because we have to remove and rebuild a bunch of diesel fuel plumbing.

This is hard. I don't even think I know how to tackle this. I do know that involves removing lot of 1/4" OD flare-fit fuel tubing. Ideally, it would be "simply" replaced with marine-grade diesel fuel-capable hose.